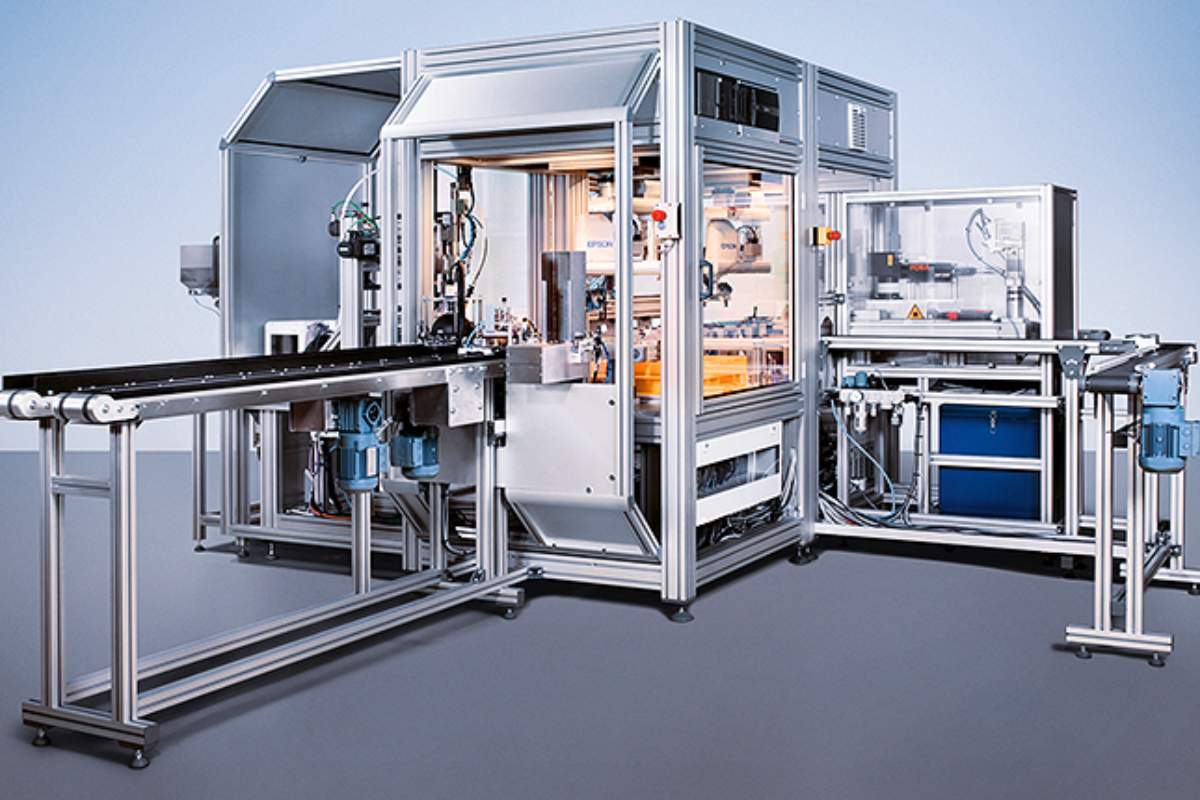

In today’s fast-paced manufacturing environment, efficiency and productivity are critical. One effective way to achieve this is through workcell design and optimization. A workcell is a defined area in a manufacturing facility where specific tasks are performed. By strategically arranging resources, equipment, and workflows, businesses can significantly enhance their operational efficiency. This article delves into the principles of workcell design and optimization, providing insights into best practices and benefits.

Understanding Workcell Design

Workcell design refers to the process of creating a layout that supports a specific manufacturing process. It involves organizing equipment, materials, and labor to streamline operations and minimize waste. A well-designed workcell can lead to improved productivity, reduced cycle times, and enhanced product quality.

Key Principles of Workcell Design

- Flow Optimization: One of the core principles of workcell design and optimization is to establish a smooth flow of materials and information. This involves arranging workstations in a sequence that aligns with the manufacturing process, minimizing unnecessary movement and handling.

- Flexibility: As market demands change, the ability to adapt the workcell layout becomes crucial. A flexible design allows for easy reconfiguration of workstations and equipment to accommodate different products or production volumes.

- Space Utilization: Effective use of space is vital in workcell design. This includes not only the physical layout but also the vertical space in a facility. Utilizing shelves, racks, and multi-level workstations can maximize productivity within a limited area.

- Worker Ergonomics: Designing workcells with worker ergonomics in mind enhances employee comfort and efficiency. Proper workstation heights, tools within reach, and adequate lighting can reduce fatigue and increase output.

- Quality Control: Integrating quality control measures directly into the workcell design can help catch defects early in the process. This can involve placing inspection stations at strategic points or incorporating automated quality checks.

The Optimization Process

Once a workcell design is in place, the next step is optimization. This involves continuously improving the work cell’s efficiency and effectiveness through various techniques.

Techniques for Optimization

- Lean Manufacturing: Lean principles focus on minimizing waste without sacrificing productivity. By applying lean methodologies to workcell design and optimization, businesses can identify and eliminate non-value-adding activities.

- Value Stream Mapping (VSM): VSM is a powerful tool used to visualize the flow of materials and information throughout the workcell. By mapping out each step in the process, manufacturers can identify bottlenecks and areas for improvement.

- Standard Operating Procedures (SOPs): Establishing clear SOPs for each task within the workcell can enhance consistency and reduce errors. SOPs serve as guidelines for employees, ensuring everyone follows the same processes.

- Performance Metrics: Regularly measuring performance metrics is essential for effective optimization. Key Performance Indicators (KPIs) such as cycle time, throughput, and defect rates can provide insights into the workcell’s performance and highlight areas for improvement.

- Employee Involvement: Engaging employees in the optimization process can lead to valuable insights and improvements. Workers often have firsthand knowledge of inefficiencies and can suggest practical solutions.

Benefits of Workcell Design and Optimization

Investing in workcell design and optimization yields numerous benefits for manufacturers. These advantages not only enhance operational efficiency but also contribute to long-term sustainability.

- Increased Productivity: A well-designed workcell can lead to higher output rates as tasks are completed more quickly and efficiently. This increase in productivity translates to better utilization of resources and improved profitability.

- Reduced Lead Times: By streamlining workflows and minimizing delays, businesses can significantly reduce lead times. This agility allows manufacturers to respond more effectively to customer demands.

- Enhanced Quality: The integration of quality control measures in workcell design helps maintain high product standards. Consistent quality leads to greater customer satisfaction and reduced returns.

- Lower Operating Costs: Workcell design and optimization can help reduce operating costs by minimizing waste, improving labor efficiency, and lowering inventory levels. These savings can have a substantial impact on a company’s bottom line.

- Improved Employee Morale: A well-optimized workcell contributes to a safer and more comfortable working environment. Employees are more likely to feel valued and engaged when their work conditions are improved, leading to higher job satisfaction and retention rates.

Real-World Applications

Several industries have successfully implemented workcell design and optimization to improve their operations. For instance:

- Automotive Manufacturing: Companies in this sector use work cells to streamline assembly lines, enabling faster production while maintaining quality standards.

- Electronics Assembly: In the electronics industry, workcell optimization can involve configuring workstations for quick assembly and testing of components, reducing cycle times and defects.

- Food Processing: Workcells in food manufacturing are designed to facilitate smooth processing, packaging, and quality checks, ensuring compliance with health regulations and enhancing efficiency.

Conclusion

In conclusion, workcell design and optimization a critical aspects of modern manufacturing that can significantly improve efficiency, productivity, and quality. By understanding the principles of workcell design and employing effective optimization techniques, manufacturers can create a competitive advantage in an increasingly challenging marketplace. Investing in these strategies not only leads to immediate operational benefits but also supports long-term business sustainability. As industries continue to evolve, the importance of work cell design and optimization will only grow, making it a vital focus for manufacturers aiming for success.

Found this article valuable? Explore more insights in our Enterprise Chronicles.