The clatter of metal chips hitting the workshop floor tells a story as old as industry. From ancient artisans carving statues to today’s computer-controlled machines shaping aerospace parts, the principle behind subtractive manufacturing remains constant: begin with more than you need, then remove what does not belong. This approach has quietly powered industrial progress for centuries and continues to define how countless everyday products are made.

Subtractive manufacturing is one of the most reliable and versatile production methods today. Instead of building parts layer by layer, it transforms solid blocks of material into finished products by systematically removing excess. Its unmatched precision, superior surface quality, and ability to handle diverse materials have made it essential across industries where accuracy and durability matter most. Whether it’s prototypes or large-scale production, understanding this manufacturing is key.

This article will discuss its processes, compare it with other methods, review material options, and see why industries still depend on it.

What is Subtractive Manufacturing?

The subtractive method encompasses any production process where material is removed from a solid workpiece to create the desired final form. This manufacturing approach starts with raw material stock such as metal bars, plastic blocks, or composite sheets, then uses various cutting, drilling, and finishing techniques to achieve precise dimensions and geometries.

The process relies heavily on computer-controlled machinery, particularly CNC (Computer Numerical Control) systems, which translate digital design files into exact tool movements. Engineers create detailed CAD models of the intended part, then specialized CAM (Computer Aided Manufacturing) software generates the precise instructions that guide cutting tools through the material removal process.

Modern subtractive production operates on principles of controlled precision that allow tolerances as tight as 0.025 millimeters. This exceptional accuracy results from the predictable nature of material removal processes, where cutting tools follow predetermined paths to achieve exact specifications. The solid material foundation provides inherent structural integrity, making parts produced through these methods particularly suitable for demanding applications where reliability cannot be compromised.

Key Subtractive Manufacturing Processes

This type of manufacturing encompasses several distinct processes, each optimized for specific materials and geometries. These techniques form the backbone of modern precision manufacturing across multiple industries.

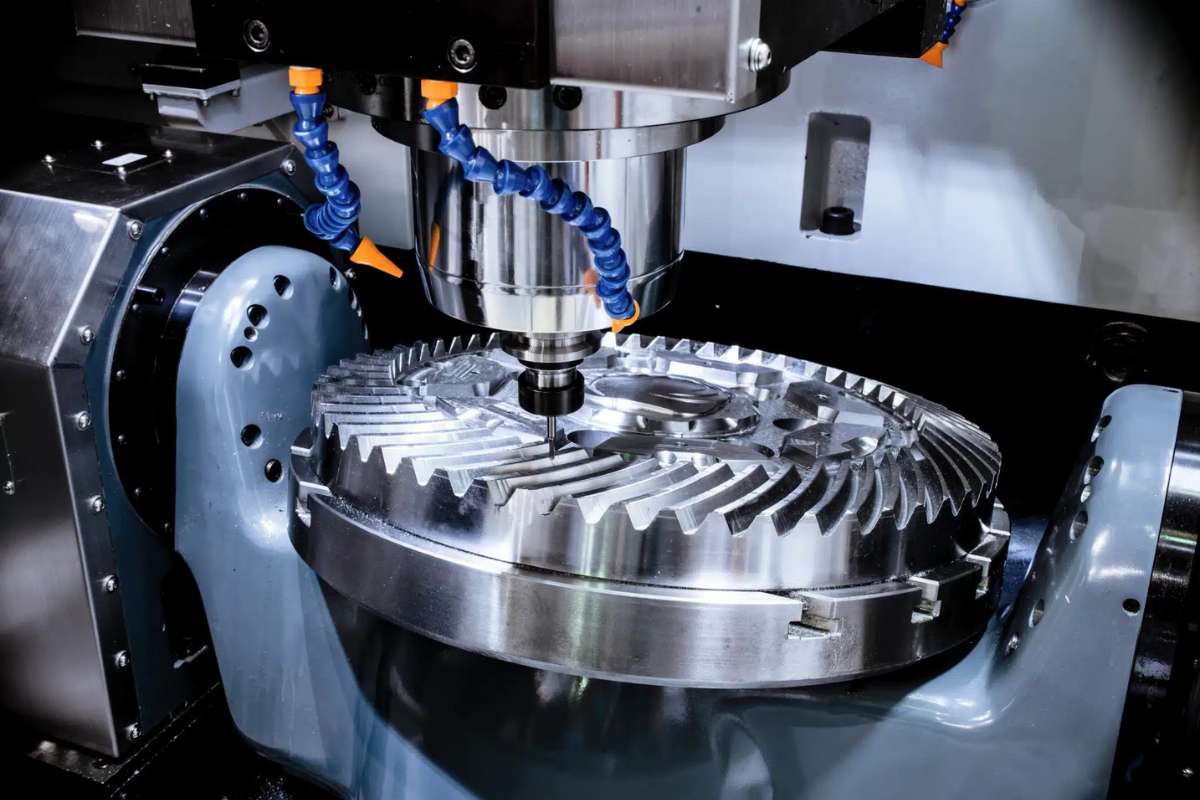

1. CNC Milling

CNC milling is the most versatile subtractive process, using rotating cutting tools to remove material from stationary workpieces. Multi-axis milling machines can move cutting tools simultaneously in three, four, or five directions, creating complex three-dimensional shapes with undercuts and intricate surface details. This process excels at producing parts with pockets, slots, and contoured surfaces that would be difficult to achieve through other methods.

The flexibility of CNC milling makes it suitable for everything from simple brackets to complex aerospace components. Advanced five-axis machines can reach challenging angles in a single setup, reducing production time while maintaining precision across all surfaces.

2. CNC Turning

Turning processes rotate the workpiece while stationary cutting tools shape the material, making this technique ideal for producing cylindrical components. Engine shafts, bushings, couplings, and threaded fasteners represent typical turning applications. The rotational motion allows for excellent surface finishes on round parts while maintaining precise dimensional control.

Modern CNC lathes can incorporate additional tooling for drilling, threading, and even milling operations, creating complete parts in single setups. This capability reduces handling time and improves accuracy by eliminating multiple machine transfers.

3. CNC Drilling

Drilling creates precise holes for fasteners, fluid passages, and alignment features. While seemingly straightforward, precision drilling requires careful consideration of factors like drill bit geometry, feed rates, and coolant application to prevent issues such as hole wandering or poor surface finish.

Advanced drilling operations can include angular holes, threaded holes, and counterboring, all controlled through CNC programming. These capabilities make drilling essential to milling and turning operations in complete part production.

Advanced Subtractive Techniques

Beyond traditional machining, subtractive techniques include specialized processes for specific applications. Electrical Discharge Machining (EDM) uses controlled electrical sparks to remove material from hard metals, enabling the creation of complex cavities in tool steels. Laser cutting provides precision material removal for thin sections and intricate two-dimensional shapes. Waterjet cutting can handle thick materials and complex substances like stone or composites using high-pressure water streams.

Materials Compatible with Subtractive Manufacturing

One of the greatest strengths of subtractive production lies in its compatibility with an extensive range of materials. This versatility enables manufacturers to select optimal materials based on performance requirements rather than process limitations.

1. Metals

Metal processing represents a cornerstone application for subtractive manufacturing. Aluminum alloys offer excellent machinability and lightweight properties, making them popular for aerospace and automotive applications. Stainless steel provides corrosion resistance and strength for medical devices and food processing equipment. Titanium alloys deliver exceptional strength-to-weight ratios for high-performance applications, though they require specialized tooling and techniques.

Steel variants from mild carbon steels to exotic superalloys can all be processed through subtractive methods. The ability to work with such diverse metallic materials gives subtractive production a significant advantage in applications requiring specific mechanical properties.

2. Plastics and Polymers

Engineering plastics form another major category of materials suitable for subtractive manufacturing. ABS provides good impact resistance and dimensional stability for prototypes and production parts. Polycarbonate offers optical clarity and toughness for transparent components. PTFE delivers chemical resistance and low-friction properties for specialized applications.

Nylon and other high-performance polymers can be machined to create functional parts with excellent wear resistance. The ability to machine plastics allows rapid prototyping and low-volume production without expensive tooling.

3. Composites and Specialty Materials

Subtractive manufacturing can also process composite materials like wood, glass, and stone. Carbon fiber composites, while challenging to machine, can produce lightweight structural components. Even materials like foam and ceramics can be shaped through appropriate subtractive techniques.

Advantages of Subtractive Manufacturing

The enduring popularity of this manufacturing stems from several key advantages that make it indispensable for precision manufacturing applications.

1. Dimensional Accuracy and Surface Quality

Subtractive manufacturing delivers exceptional dimensional accuracy with tolerances achievable down to 0.025 millimeters. This precision results from the controlled nature of material removal processes and the rigid setup of cutting tools and workpieces. The smooth surface finishes often eliminate the need for secondary operations, reducing production time and costs.

Parts produced through subtractive methods maintain consistent quality across production runs, as the process parameters remain stable once established. This repeatability makes the subtractive process ideal for applications where part-to-part consistency is critical.

Also Read :- Quality Control Processes: Ensuring Excellence in Every Step

2. Material Properties and Structural Integrity

Starting with solid material blocks ensures that finished parts retain the full structural properties of the base material. This characteristic becomes particularly important for high-stress applications where material integrity cannot be compromised. The absence of layer interfaces or bonding concerns gives subtractive parts predictable mechanical behavior.

Heat treating and other material enhancement processes can be applied to stock material before machining, allowing for optimized material properties in the final part.

Also Read :- Resource Allocation in Production: Optimizing Efficiency and Output

3. Scalability and Production Flexibility

Subtractive process scales effectively from single prototypes to large production runs. Setup costs can be amortized across higher volumes, making the process increasingly economical for larger quantities. The ability to machine different materials on the same equipment provides production flexibility that adapts to changing requirements.

Also Read :- The Rise of Industry 4.0: Revolutionizing Manufacturing and Beyond

Limitations of Subtractive Manufacturing

Despite its many advantages, the subtractive method faces constraints that influence when and how it should be applied.

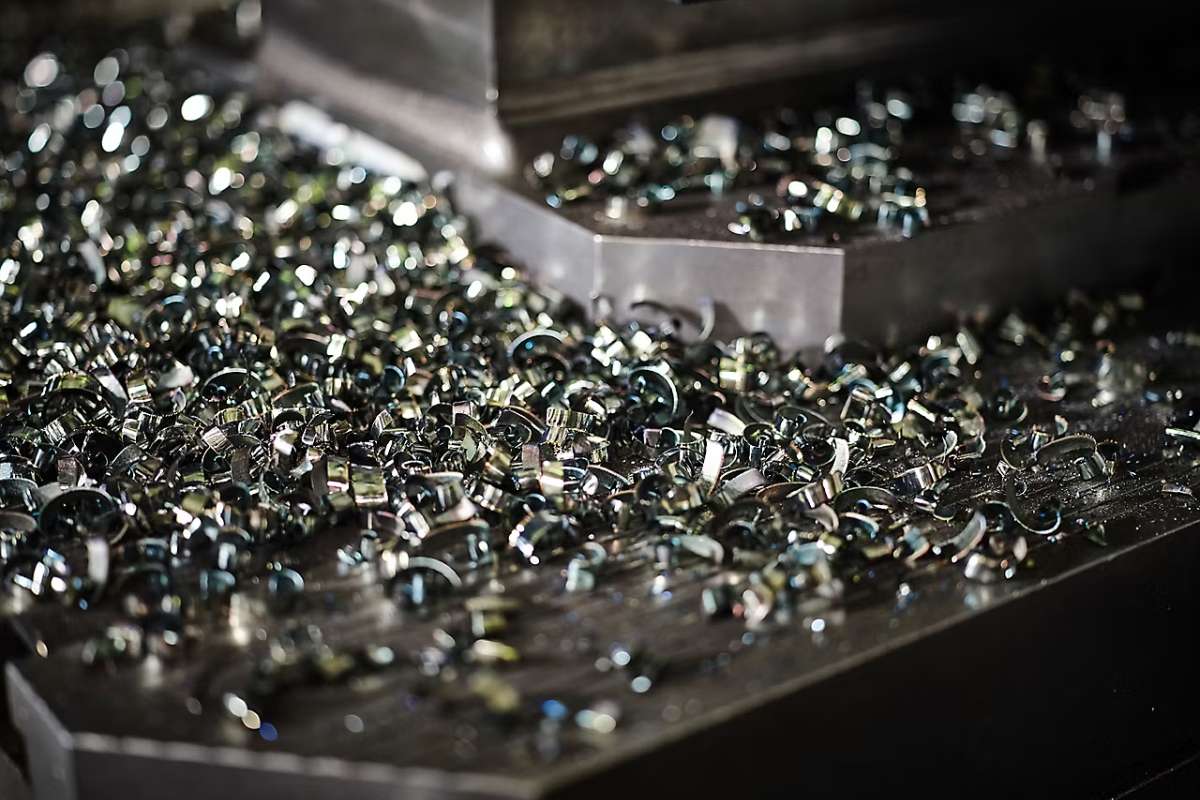

1. Material Waste

The fundamental nature of material removal creates waste in the form of chips, shavings, and offcuts. While these materials can often be recycled, the waste represents material and energy costs that must be factored into production decisions. Waste costs can become significant for expensive materials like titanium or specialty alloys.

2. Geometric Limitations

Subtractive manufacturing works from the outside, limiting the complexity of internal features that can be produced. Deep cavities, internal channels, and complex hollow structures may require multiple setups or specialized tooling. Some geometries easily produced through additive methods remain challenging or impossible through subtractive approaches.

3. Setup and Tooling Requirements

Precision subtractive operations require careful setup, appropriate tooling, and skilled operators. Custom fixtures may be needed for complex parts, adding to setup costs and lead times. Tool wear requires ongoing monitoring and replacement, particularly when machining hard materials.

Subtractive vs Additive Manufacturing

The relationship between subtractive and additive manufacturing represents complementary rather than competing approaches to production.

1. Speed and Cost Considerations

For simple to moderate complexity parts in higher volumes, subtractive manufacturing typically offers faster production rates and lower per-piece costs. Additive manufacturing excels for low volumes of complex parts, particularly those with internal features that would not be easy to machine.

Setup time favors additive manufacturing for one-off parts, while the subtractive method becomes more efficient as volumes increase. The break-even point depends on part complexity, material requirements, and production quantities.

2. Material and Finish Requirements

Subtractive manufacturing supports a much broader range of materials, including high-performance metals and engineering plastics that may not be available for additive processes. Surface finish quality typically favors subtractive methods, often eliminating post-processing requirements.

The subtractive process frequently provides the only viable production path when specific material properties or surface characteristics are required.

3. Hybrid Manufacturing Approaches

Many modern manufacturers combine both approaches in hybrid workflows. Additive manufacturing might create rough forms quickly, followed by subtractive production to achieve final dimensions and surface quality. This combination leverages the strengths of both processes while minimizing their individual limitations.

Industry Applications

Subtractive manufacturing is a critical production method across numerous industries where precision and reliability are paramount.

1. Aerospace Industry

The aerospace sector relies heavily on subtractive production to produce critical components like turbine blades, structural elements, and engine parts. The ability to work with specialized alloys and achieve tight tolerances makes this process essential for safety-critical applications. Complex geometries required for aerodynamic efficiency can be achieved through multi-axis machining operations.

2. Automotive Manufacturing

Engine blocks, transmission components, and precision mechanical parts represent major applications for this manufacturing in automotive production. The process supports prototype development and high-volume production, adapting to the industry’s rapid product development and cost-effective manufacturing needs.

3. Medical Device Production

Surgical instruments, orthopedic implants, and precision medical components benefit from the accuracy and material compatibility of subtractive manufacturing. Biocompatible materials like titanium and stainless steel can be processed to meet stringent medical requirements. The ability to achieve smooth surface finishes becomes particularly important for implantable devices.

4. Electronics and Consumer Products

Precision housings, heat sinks, and mechanical components for electronic devices frequently utilize these manufacturing processes. The ability to create complex cooling channels and precise mounting features makes this approach valuable for thermal management applications.

5. Future of Subtractive Manufacturing

Subtractive production is advancing through automation, robotics, and innovative technologies that improve efficiency, reduce waste, and extend tool life. Hybrid systems combining additive and subtractive processes enable complex part production, while sustainable practices such as energy efficiency and closed-loop recycling address environmental concerns. These innovations ensure subtractive methods remain competitive and relevant. With their proven precision, versatility, and reliability, subtractive processes will continue to play a central role in meeting industry demands for high-quality, durable components.

Conclusion

Subtractive manufacturing has long been a foundation of modern production, valued for its accuracy, versatility, and reliability. Even as new methods emerge, its proven strengths are essential across industries. With ongoing innovation and sustainable practices, subtractive processes will remain a critical force in delivering high-quality, durable components for the future of manufacturing.