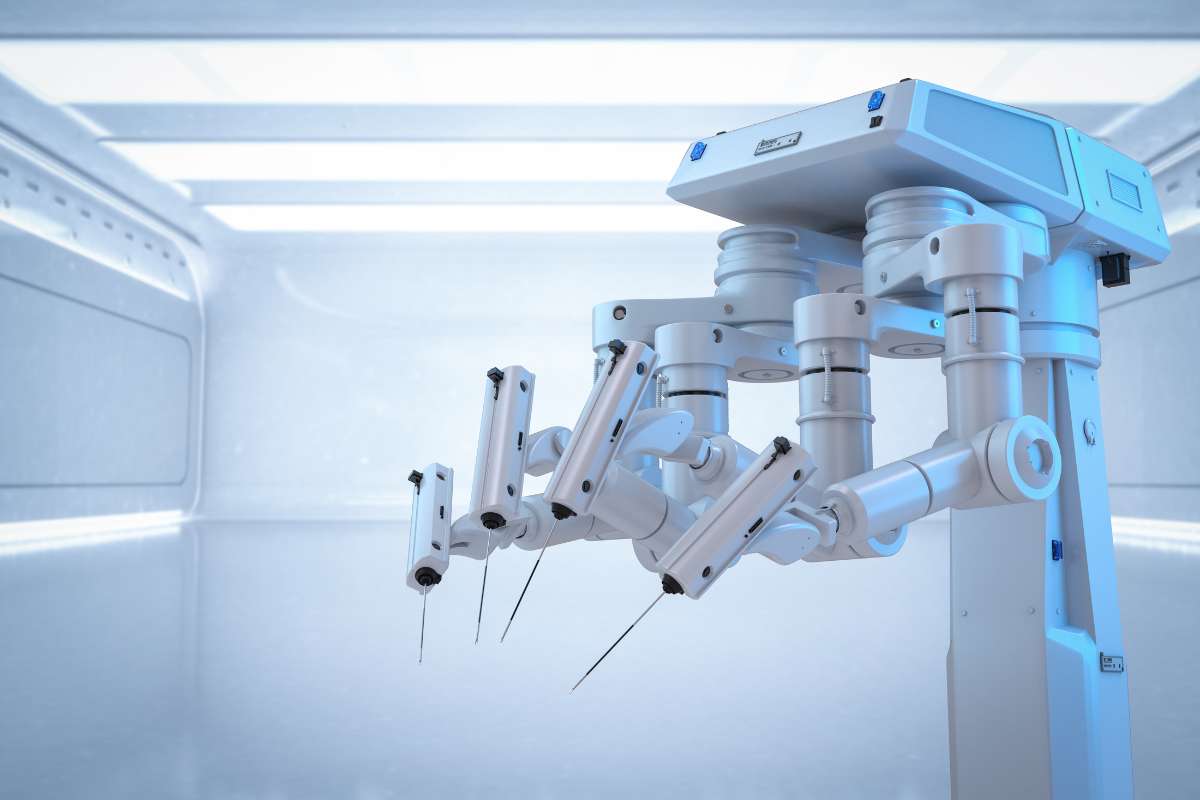

Modern healthcare demands precision, reliability, and continuous improvement. Among the most significant innovations answering these needs are robotic medical devices. These advanced machines work alongside healthcare professionals to perform tasks ranging from delicate surgical maneuvers to complex rehabilitation therapies. These medical devices enhance patient outcomes and reduce human error by combining mechanical accuracy with real-time data collection. This article explores the foundations of these systems, examines their many benefits, and considers the challenges and future directions for integrating robotic solutions into everyday medical practice.

What Are Robotic Medical Devices?

They are machines with sensors, actuators, and control systems that perform or assist in medical procedures. They range from robotic arms used in minimally invasive surgery to wearable exoskeletons that support patient movement. Guided by specialized software, these tools convert human commands into precise actions. Some systems deliver therapy automatically under supervision, while others collect data to guide clinicians in making informed choices. By extending human capabilities, robotic medical devices play an essential role in improving accuracy, reducing fatigue, and offering treatment options previously unattainable.

Historical Evolution of Automated Medical Devices

The integration of robotics into medicine began more than three decades ago. Early prototypes focused on telemanipulation for remote surgery. Over time, imaging, miniaturization, and software advances led to the first commercially available surgical robot in the 1990s. As technology matured, companies introduced systems capable of three-dimensional visualization, motion scaling, and force feedback. Today’s robotic medical devices build on these milestones, incorporating artificial intelligence for pattern recognition, cloud connectivity for expert collaboration, and modular designs that adapt to different specialties.

Categories of Robotic Medical Devices and Robotic Medical Tools

Understanding the varied types of robotic medical devices helps clarify their specific applications:

1. Surgical Robots:

These platforms translate a surgeon’s hand motions into exact instrument movements inside the patient’s body. They often include high-definition three-dimensional cameras, motion scaling, and tremor reduction to improve safety during complex procedures.

2. Diagnostic Robots:

Devices that automate imaging tasks such as ultrasound scanning or automated biopsy guidance. With consistent probe positioning and real-time feedback, they reduce operator variability and improve diagnostic accuracy.

3. Therapeutic Robots:

Systems that deliver targeted therapies. Examples include robotic infusion pumps that provide exact medication dosage and robotic exoskeletons that support rehabilitation for patients recovering from stroke or spinal injury.

4. Rehabilitation Robots:

Wearable or table-mounted devices that assist patients in regaining movement through guided exercises. They record performance metrics and adjust assistance levels as the patient progresses.

5. Assistive Robots:

Machines that help with routine tasks such as patient transfer or instrument handling in the operating room. By reducing the physical burden on staff, they contribute to workflow efficiency.

Ten Important Uses of Robotic Medical Devices

1. Enhanced Precision and Accuracy

Robotic medical devices can perform micro movements beyond human capability with motion scaling and advanced control algorithms. This precision lowers the chance of damage to surrounding tissues and improves surgical outcomes.

2. Minimally Invasive Procedures

Using small incisions rather than significant open cuts reduces trauma to the body. Patients experience less pain, shorter hospital stays, and faster return to daily activities when treated with robotic systems.

3. Improved Visualization

Many robots integrate three-dimensional, high-definition imaging. Surgeons view the operative field with greater clarity and depth perception, allowing for more exact identification of critical anatomy.

4. Reduction of Surgeon Fatigue

Long surgeries can strain surgeons physically and mentally. Robotic medical devices maintain consistent steadiness and eliminate tremor regardless of procedure length, reducing fatigue and maintaining performance quality.

5. Data Collection for Continuous Improvement

Detailed tracking of instrument movements and applied forces creates rich datasets. Analysis of this information supports research, refines techniques, and builds evidence for best practices.

6. Customizable Patient Care

Systems can be configured to suit individual anatomical variations and treatment requirements. Custom tool trajectories and force thresholds improve safety for patients with unique physiological conditions.

7. Remote Collaboration

In areas lacking specialists, remote operation allows experts to guide local practitioners. This capability expands access to advanced surgeries and supports training in real time.

8. Accelerated Learning Curve

Simulation modules and step-by-step guidance help new users gain proficiency quickly. Surgeons train on virtual models before live operations, reducing patient risks and speeding up credentialing.

9. Economic Efficiency

Although initial purchase costs can be high, robotic medical devices often yield savings through reduced complications, shorter hospital stays, and higher procedure throughput. Improved outcomes also lead to greater patient satisfaction.

10. Integration with Emerging Technologies

Robotic devices work hand in glove with imaging, cloud connectivity, and analytics innovations. Real-time image overlays and remote expert support reinforce decision-making and expand clinical possibilities.

Case Studies: Real World Impact

1. Prostate Cancer Surgery

A leading hospital introduced a robotic system for prostatectomies. Postoperative data showed a fifty percent reduction in blood loss, and a community of patients reported less discomfort and quicker recovery compared to traditional open surgery.

2. Stroke Rehabilitation

In a rehabilitation center, patients recovering from stroke used robotic exoskeletons for guided walking sessions. Customized assistance levels enhanced muscle strength and coordination, cutting therapy time by nearly twenty percent.

3. Automated Ultrasound Scanning

A diagnostic clinic deployed a robotic scanner for abdominal ultrasounds. Consistent probe positioning improved image quality and reduced repeat scans by thirty percent, increasing patient throughput.

Current Challenges and Considerations

Despite clear benefits, several factors influence the adoption of robotic medical devices:

- High Initial Investment

- Up-front hardware, training, and maintenance costs can be a barrier for smaller institutions.

- Technical Complexity

- Systems require specialized staff and ongoing support. Facility teams must manage software updates, instrument calibration, and user credentialing.

- Regulatory Approvals

- Navigating regional regulatory pathways demands rigorous testing and clinical evidence. Approval timelines can delay market entry.

- Reimbursement Policies

- Insurance coverage varies by procedure and region. Lack of standardized reimbursement guidelines may limit patient access.

- User Acceptance

- Clinicians may be hesitant to adopt new workflows. Effective training programs and demonstration of clinical value are essential for acceptance.

Future Trends in Robotic Medical Devices

Looking ahead, several developments will shape the next generation of robotic medical tools:

- Greater Autonomy

- Advances in machine learning allow specific tasks to be performed semi-autonomously, such as suturing or tissue dissection, under clinician supervision.

- Smaller and More Portable Platforms

- Miniaturization will produce more compact devices suitable for outpatient clinics and field hospitals.

- Enhanced Haptic Feedback

- Improved force sensing will restore a sense of touch for surgeons, allowing them to feel tissue resistance changes.

- Cloud-Based Collaboration

- Real-time data sharing will connect treatment centers globally, facilitating expert consultations and collaborative surgeries.

- Cost Reductions through Modular Design

- Modular robots will allow hospitals to upgrade specific components rather than replace entire systems, lowering the total cost of ownership.

Implementation Best Practices

To maximize the benefits, healthcare organizations should:

- Establish a multidisciplinary steering committee to guide selection, training, and evaluation.

- Develop comprehensive training curricula with simulation and proctored cases.

- Monitor performance metrics and patient outcomes to refine protocols.

- Engage with manufacturers for service agreements and software updates.

- Educate patients on the advantages and risks to foster informed consent.

Conclusion

Robotic medical devices represent a pivotal shift in how care is delivered. By merging mechanical precision with clinical insight, these systems enhance safety, improve recovery, and expand the reach of advanced treatments. As technology continues to evolve, hospitals that embrace robotic solutions stand to offer higher quality, more personalized care. The future of healthcare will rely on these intelligent machines to redefine what is possible in patient treatment.

FAQs

1. What distinguishes robotic medical devices from conventional tools?

Robotic medical tools provide motion scaling, tremor reduction, and three-dimensional visualization, features unattainable with standard instruments.

2. Are surgeries using robotic systems more expensive?

Initial costs are higher, but reduced complication rates and shorter hospital stays often offset expenses.

3. Can small hospitals afford these systems?

Partnerships, shared service models, and modular platforms help smaller centers gain access to advanced robotics.

4. How do patients benefit directly?

Patients experience less pain, faster recovery, and lower risk of complications thanks to precise, minimally invasive procedures.

5. What should hospitals consider before adoption?

Key factors include capital budgets, staff training, regulatory requirements, and alignment with organizational goals.

Also Read :- Robotics and Automation: Shaping the Future of Industries